In this article you will gain a basic understanding of the Automotive SPICE process model and the purpose of its application in the development of software-based systems. This will help you understand why Automotive SPICE is a great way to address upcoming system development challenges. Learn here 5 good reasons why Automotive SPICE is important for you.

What is Automotive SPICE?

Automotive SPICE (Software Process Improvement and Capability Determination) is a quality standard for evaluating business processes from a process safety and quality perspective – introduced to evaluate, compare and improve the quality of software development in the automotive industry. This standard not only takes software processes into account, but also focuses on the interaction of software, hardware and mechanics in a mechatronic system.

This quality standard results in a process model that is based on the ISO/IEC 30xx series of standards, is internationally recognized and is currently becoming the established development standard for the global automotive industry. Since 2006, the German Association of the Automotive Industry (VDA) has recommended that its members use this model as a basis for development.

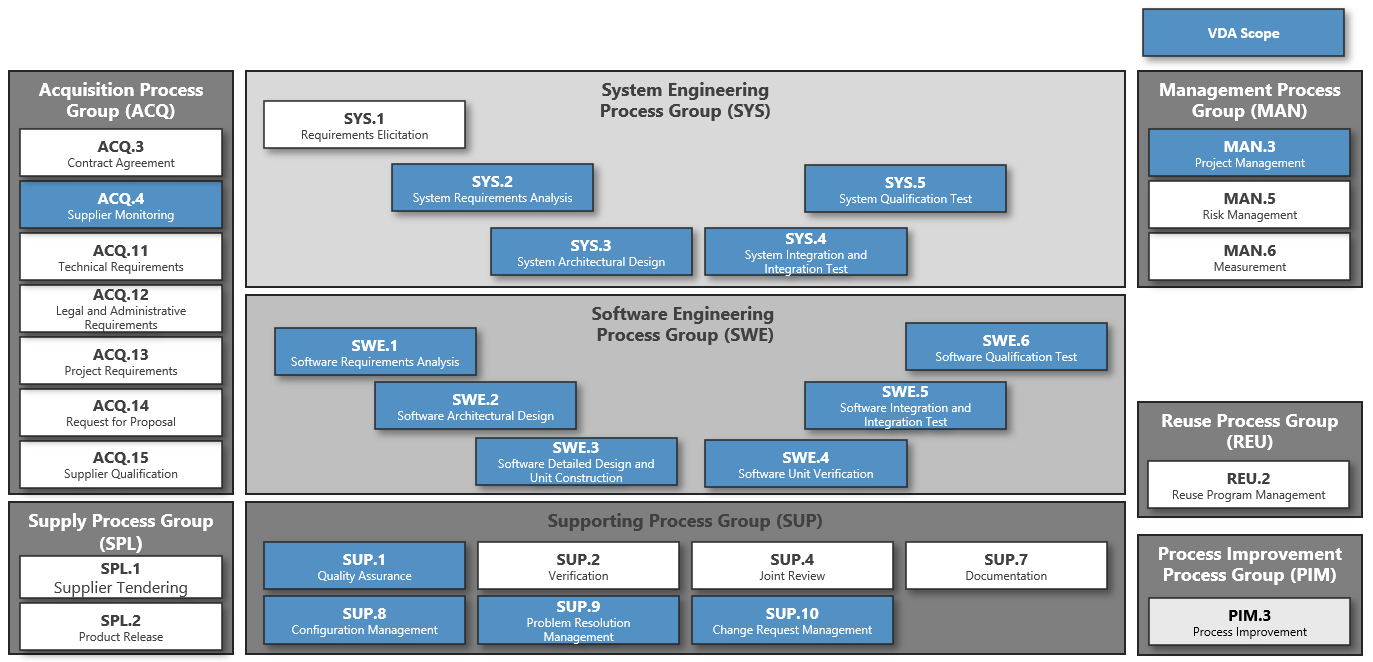

The model contains two important dimensions. First is the process dimension, which describes the defined processes with their requirements. Each process includes a detailed description of activities to be performed in a project. A second model component is the maturity dimension or capability dimension. This enables the measurement of the capability of each process. To narrow down the process dimensions, the VDA has defined the most important core processes for the development of software-based systems to 16 (see Figure 1).

Let’s take a closer look at the structure of the process dimensions. First, the process dimensions can be clustered into different process subgroups.

System Engineering Process Group (SYS):

This is where the engineering processes for creating the system specification, system architecture and associated test processes are located. This process group is only relevant if, in addition to software elements, at least one hardware or mechanical element is also the subject of development.

Software Engineering Process Group (SWE): This is where the engineering processes for the creation of the software specification, software architecture and code creation as well as the associated test processes are located.

Acquisition Process Group (ACQ): This is where the processes are located that are to be taken into account by the customer with regard to collaboration with suppliers. The core of this is the creation of the specifications and the management of supplier activities.

Supply Process Group (SPL): This is where processes are located that are to be implemented by the supplier with regard to collaboration with the customer. These include the activities of the quotation process and product delivery.

Supporting Process Group (SUP): In addition to processes for ensuring quality, this group also contains process descriptions for configuration, problem and change management.

Management Process Group (MAN): This group contains processes for describing project and risk management as well as processes for measuring projects.

Reuse Process Group (REU): This process describes the requirements to be observed when reusing project results.

Process Improvement Process Group (PIM): This is a process to plan, manage and control process improvement activities in a meaningful way.

The Process Description – A Standard for All Processes

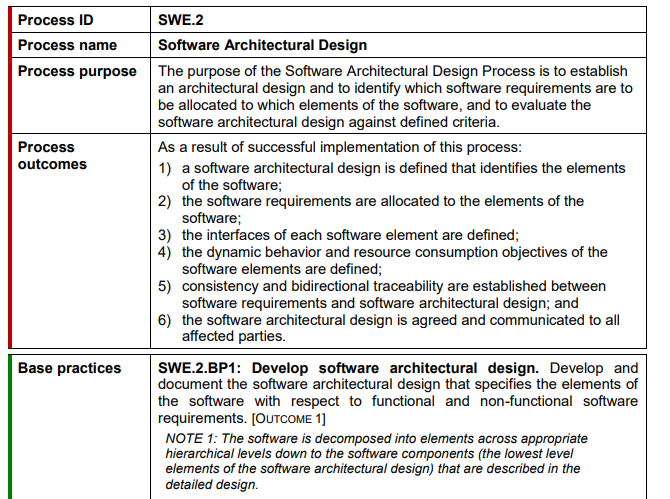

Each process is described according to an established documentation standard by ID, process name, process purpose, process outcome, basic practices, and output work products (see Figure 2).

The meaning of the elements is described below:

- ID and Process Name are used to uniquely identify the process.

- Process purpose represents the main purpose of the process in a brief description

- The process result defines the target state of an executed process

- Basic practices describe the activities to be performed to satisfy the process outcome. They serve as indicators of the process dimension and are the core elements in the evaluation of processes

The output work products represent possible work products that can be produced as part of the process. The listing is to be understood as a suggestion and thus not binding. The work products can be distributed across different work products.

The Maturity Dimensions – Capability Levels

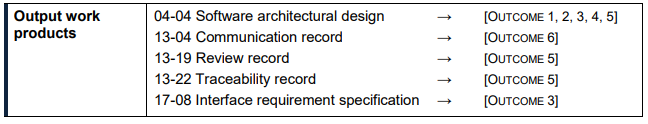

This chapter is dedicated to the consideration of the maturity level dimensions. The purpose of the maturity level dimensions is to evaluate the individual processes. In Automotive SPICE there are six different maturity levels, ranging from level 0 to level 5. These are shown in the pyramid diagram in Figure 3.

A level 0 process exists when its purpose is not fulfilled. That is, no or almost no evidence of the results to be produced exists.

A Level 1 process is referred to as an accomplished process. This means that the process basically fulfills its purpose. This is evidenced by proven results. A formal process description is not yet required at this level.

From level 2 onwards, the quality aspect is brought into focus. The activities required to implement the process are planned and tracked. An overview of the available resources with defined responsibilities exists. All work results produced are created and managed in a structured manner.

At level 3, a standard process is defined, which is valid for several projects. For this superior standard process the same quality characteristics apply as on level 2. A project can either implement this process 1:1 or adapt it according to clearly defined rules for its requirements.

From level 4 onwards, a quantitative measurement method is used for the targeted control of the process. The implementation of the process is monitored using metrics and adjusted if necessary.

Level 5 builds on the knowledge gained from Level 4. Using the knowledge gained, the process is continuously improved through innovative ideas to achieve the set goals.

The Three Most Important Factors for Successful Implementatio

Finally, we would like to share with you the three most important aspects for a successful implementation of process improvement projects.

If you decide to implement an improvement project in your company, the management level should initiate this initiative. The willingness of management to take this project seriously is the basic prerequisite for the improvement project to be understood as an organizational change. This also means that management must be informed at regular intervals about the status of progress. This signals to the employees involved that their work is desired and recognized.

The introduction of Automotive SPICE compliant processes is not only the task of the quality department, because the standard does not describe how to do something. Automotive SPICE only describes what has to be done. This delimitation means that, in addition to quality experts, subject matter experts from the respective process areas must also be involved. This ensures that the newly defined processes are applicable in the organization or department. The framework for such an improvement project is accompanied by adequate process management.

In order to use the available resources efficiently, a structured approach is necessary to develop a consistent process landscape. An orderly management to create this process landscape aims to define the individual elements and to leverage synergies between them.

We would be happy to advise you on Automotive SPICE and accompany your project with concrete recommendations for action.